Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

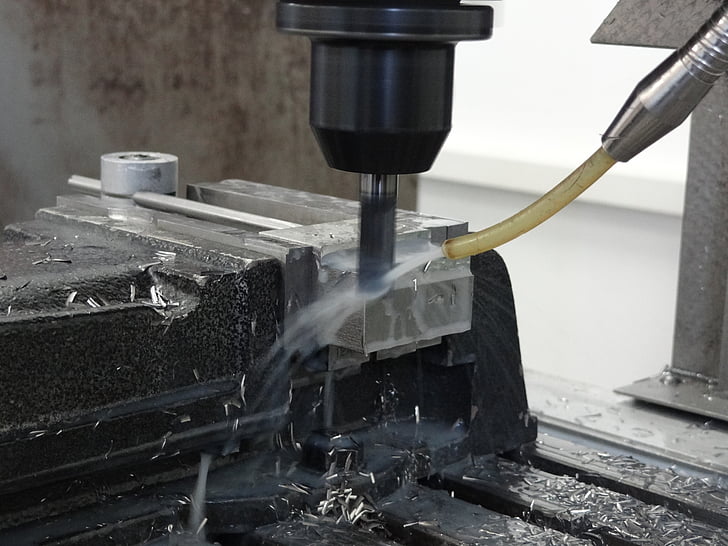

Having an understanding of the different types of CNC machines which can help us design for it properly to save our time and money.

More than that we will have some basic ideas with the limitations and benefits of each different type of CNC machine and how the limitations and benefits of each different machine type.

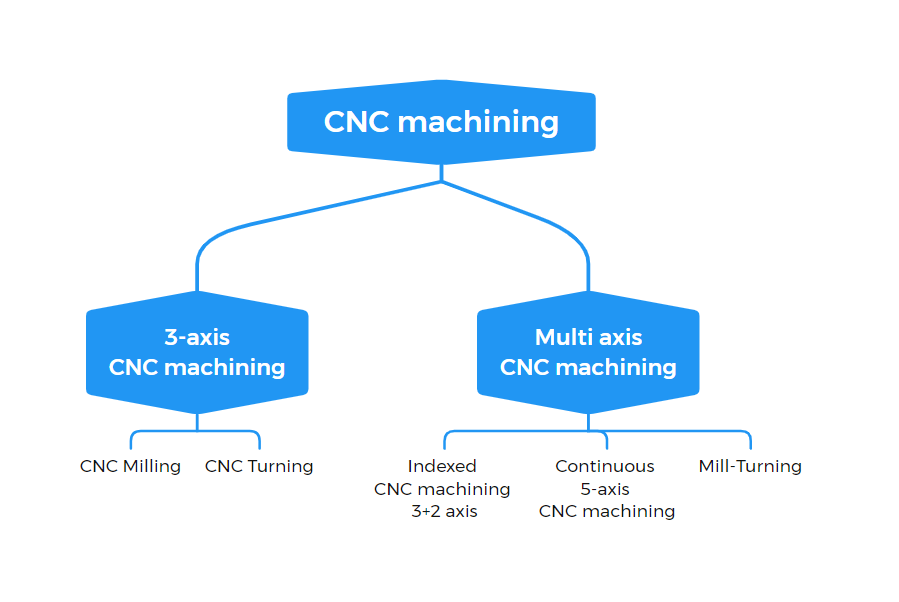

CNC machines can be broken up into three axis CNC machines four axis CNC machines, five axis CNC machines and multi axis CNC machines.

Three axis machines are CNC milling or CNC turning machines which also known as lathe. CNC milling machines and CNC turning machines allow the movement of the cutting tool, relative to the workpiece, in three linear axis: left-right, back-forth and up-down also we call the x, y and z axes. So, the workpiece is fixed when machinist is operating with 3-axis machining.

It is still a quite common machining process nowadays. This is a relatively simple type of CNC machining that allows the manufacture of products with simple structures. That is to say, it is not suitable for production of complex machining parts.As it can only cut in three axes, it also may be slower than four-axis or five-axis CNC comparing the machining speeds because the workpiece may need to be manually repositioned to obtain the desired shape.

Four-axis CNC milling, there is a fourth axis is added to the motion of the cutting tool, which rotates around the x-axis. Therefore, Now we have four axes – the x-axis, y-axis, z-axis and the a-axis (which rotates around the x-axis). the workpiece can be rotated at some four-axis CNC machines which is called the B-axis. So that the Four-axis cnc machine act as a milling machine and a lathe machine at the same time.

Five-axis machining CNC machine tool can control three linear coordinate axes and two rotary coordinate axes to move at the same time, so that the tool and workpiece can be cut according to the specified motion trajectory. Five-axis CNC machining center is a CNC machine tool integrating milling, fine milling, fine boring, drilling, reaming, etc., which can process sheet metal, molds and other small and medium-sized hardware parts and other fields. Commonly used in the field of aerospace (fuselage parts, impellers, blades, spiral grooves and other high-precision parts) and medical equipment, chute beveled holes, complex curved surface hardware parts.

Five-axis CNC milling has an additional axis of rotation compared to four-axis NC. It is the fifth axis. And also, it is known as b-axis which is rotation around the y-axis. People used it to manufacture complex precision parts because the flexibility of 5-axis CNC machining. For example, medical parts of artificial prosthetics or bones, aerospace parts, titanium parts, oil and gas machinery parts, military products, etc.

Multi-axis CNC machining generally means 5-axis CNC machining. Multi-axis CNC machining can control more than 4 coordinate axes at the same time to carry out multi-process processing such as milling, drilling etc.

We Componing owned all types machines mentioned above with experienced specialists and manufacturing technologies can meet your machining needs. Welcome to contact us online.