Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

CNC Machining inspection generally requires attention to below two aspects:

1. Inspection procedures: Initial Production Inspection, PQC: Process Quality Control, OQA: Outgoing Quality Assurance.

The status of inspection is divided into: qualified, unqualified, to be inspected, to be determined after inspection; According to the requirements of the inspection process regulations, check whether the quality characteristics of the products in each stage really meet the requirements: pass the inspection and approve the production and processing. If the inspection fails, the unqualified product is treated, and the reasons for the unqualified are analyzed. After the improvement measures are taken, the product will continue to be inspected until it is qualified.

2. Test method – refers to how to test and test standards. The inspection of machining parts is generally based on mechanical drawings and the product is inspected by means of inspection instruments and measuring tools.

Objective: To integrate the inspection work with the process control, to avoid the quality problems or possible quality problems of each process, to eliminate the non-conforming product, so that it cannot be put into the lower order or factory, thus achieving the purpose of the process control.

Traditional machining testing instruments include micrometers, Vernier Caliper, level instrument, height measuring instrument, magnetic meter holders and various plug gauges, needle gauges, feeler gauges, etc.

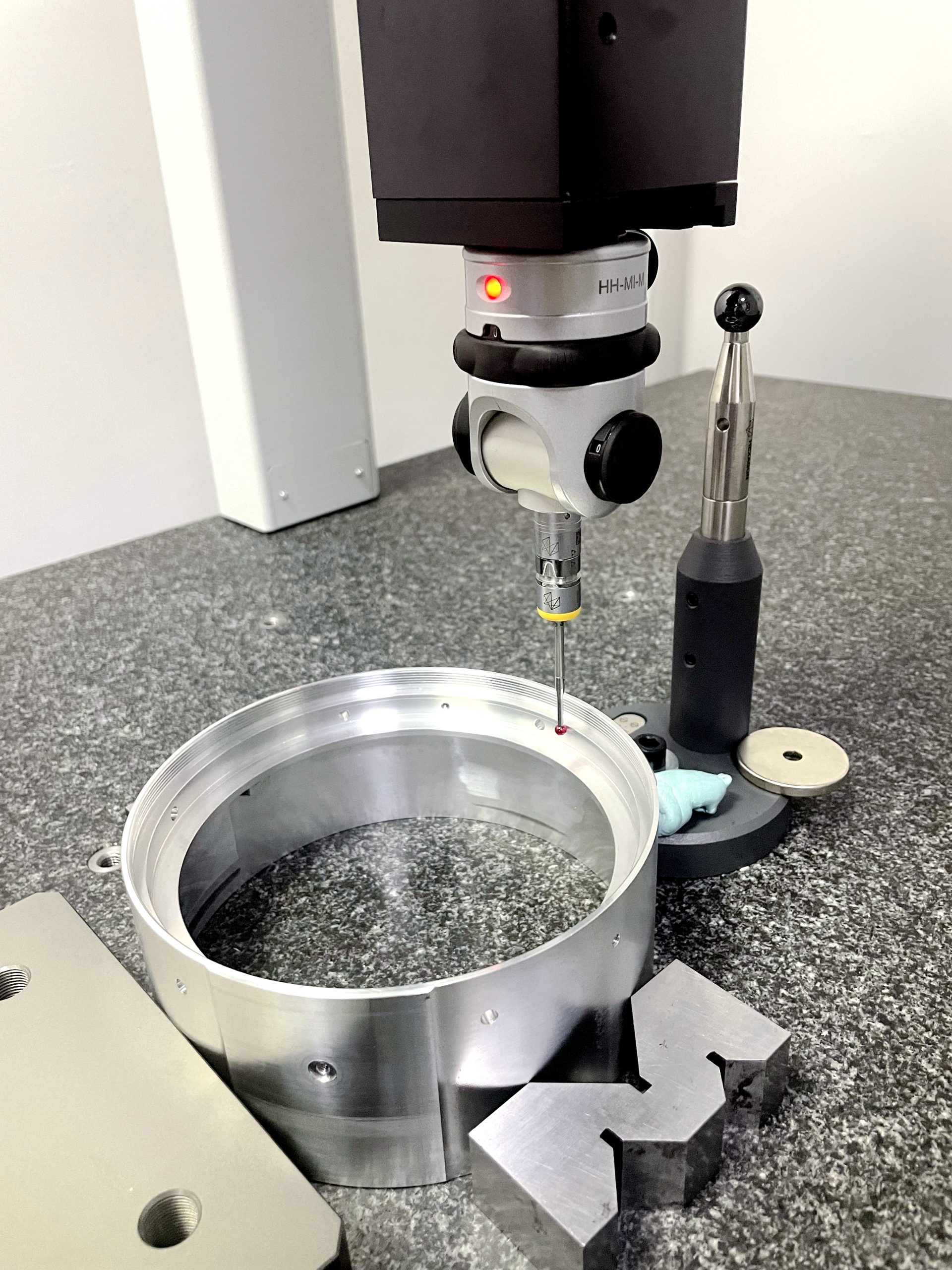

Modern machining testing instruments include optical collimator, quadratic element, projector, three-dimensional measuring instrument, theodolite and laser detector.

The following introduces several testing equipment that we commonly used in CNC machining:

1. Dental gauge

Dental gauge is used to experience the quality of the thread, is made according to the national standard, there are external threads and internal threads, the external thread is understood as a screw to test the standard of the nut, the internal thread can be solved into the nut used to test the standard of the screw.

2.Needle gauge

Needle gauge is the standard for inspecting the inner hole, generally there are two, one for the general gauge, one for the gauge, just like a metal rod, the gauge must be put into the hole, the gauge must not enter, any one of the two errors means that the product size is unqualified.

3. Vernier caliper

Vernier caliper is a measure of length, inner and outer diameter, depth of inspection tools. The vernier caliper consists of two parts: the main ruler and the vernier attached to the main ruler that can slide. The main ruler is generally measured in millimeters, and the vernier has 10, 20 or 50 divisions, according to the different divisions, the vernier caliper can be divided into ten-degree vernier calipers, twenty-degree vernier calipers, fifty-degree vernier calipers, etc., the vernier is 10 divisions of 9mm, 20 divisions are 19mm, 50 divisions are 49mm. There are two pairs of movable claws on the main ruler and vernier of the vernier caliper, the inner measuring claw is usually used to measure the inner diameter, and the outer measuring claw is usually used to measure length and outer diameter.

4. Micrometer

Micrometer is used to check the external inspection, inner diameter, depth as the vernier caliper, but relatively single, each specification must buy a different micrometer, such as outer diameter micrometer, inner diameter micrometer, micrometer is more accurate than the vernier caliper, can be accurate to 0.01 mm.

5. Altimeter

Altimeter is used to measure the depth dimension of the product, such as the size of one end face to another, the size measured by the altimeter is more accurate than the vernier caliper, can be accurate to 0.001mm.

Finally, the correct use of various tools and proper maintenance can also affect the accuracy and service life of the measuring tool, such as wiping clean and returning to the original position after use.

Componing is proud of the effective management and Strict Quality Control Process to ensure that the parameters are accurate. Contact us today to learn more about what we can do for your project.