Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

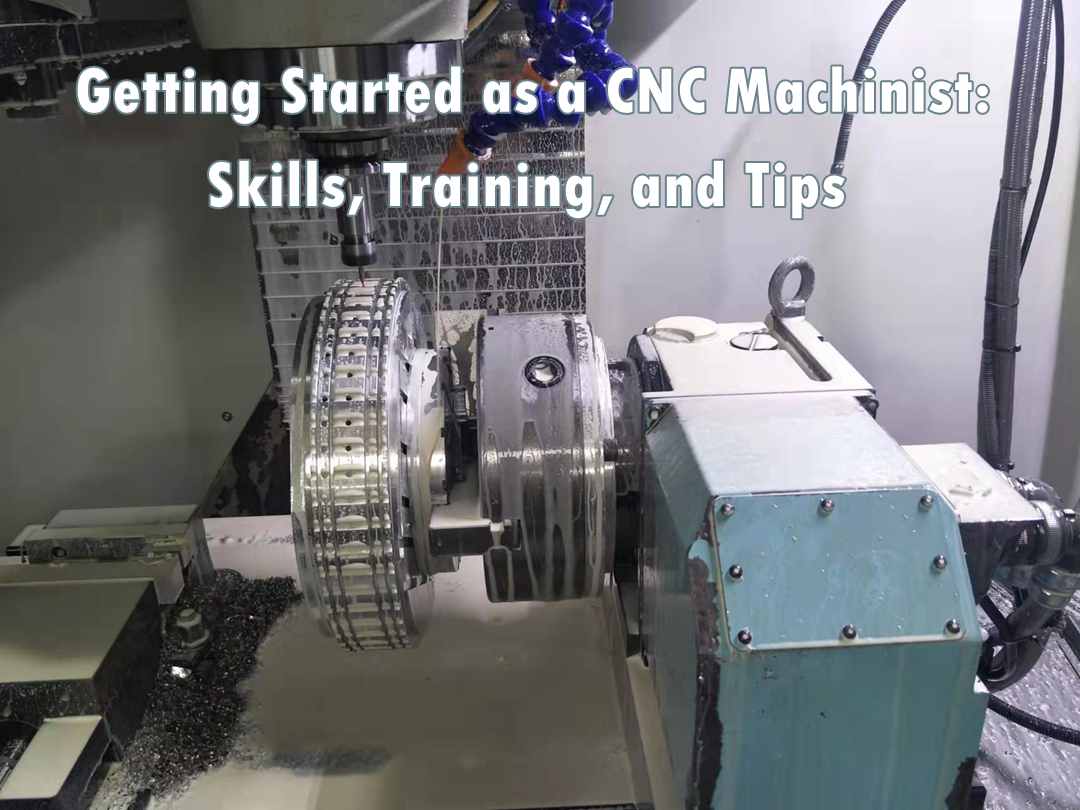

CNC machining is a cutting-edge technology that allows for precise and accurate manufacturing of complex parts and components. It is a highly specialized process that requires expertise and attention to detail.

And is known for its precision and accuracy. With this technology, manufacturers can produce parts and components with tolerances of less than a thousandth of an inch. This level of precision is not possible with traditional manufacturing methods.

In addition to precision and accuracy, CNC machining is also highly efficient and fast. The process is automated and can run 24/7, producing parts and components at a much faster rate than traditional manufacturing methods.

CNC machining is an exciting career where you get to produce high-tech components using advanced, computer-controlled manufacturing equipment. Here are the main steps to start your career as a CNC machinist:

The right mix of education, training, and experience will serve as an excellent foundation for a rewarding, lifelong career in CNC machining.

At Componing, we’re passionate about delivering top-quality CNC machined components for all your project needs. With decades of experience, we have the capabilities and expertise to handle any parts manufacturing challenge.

No project is too complex for us. We expertly perform all standard CNC operations including:

Our extensive collection of advanced CNC machines enables us to manufacture parts from prototypes up to full production runs.

Componing can machine components with simple geometries to very complex shapes, special contours, and tight tolerances. Our skilled programmers work directly with your engineering team to translate even the most intricate designs into machined parts.

We cut, shape, and fabricate all engineering materials including:

Our CNC machining expertise helps companies succeed in sectors like aerospace, defense, robotics, medical, fluid handling, and many more.

Get high-quality precision CNC machining services for custom parts manufacturing. Our fast and accurate prototyping process ensures your parts are made to exact specifications.

Contact us today to discuss your next project and see how our capabilities can help you overcome your manufacturing challenges.