Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

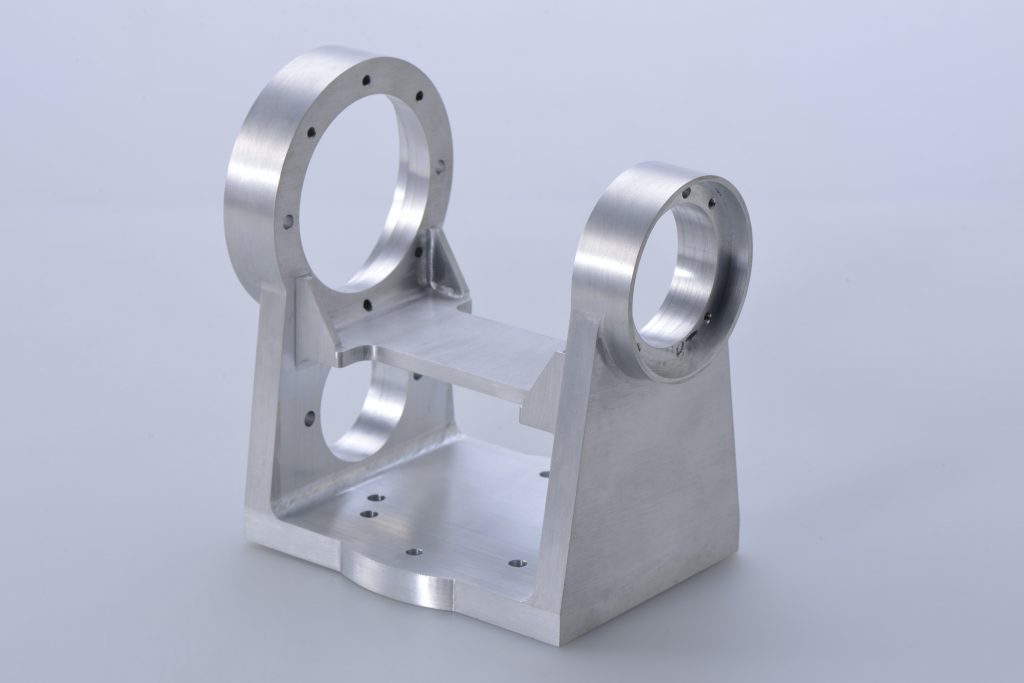

Five-axis machining accuracy and efficiency.

For example, a high-end five-axis linkage numerical control system can also perform high precision machining on complex spatial surfaces. It is also more suitable for processing automotive parts, aircraft structure parts and other modern molds.

This is also one of the important reasons why many high quality custom hardware parts five-axis processing plants can quickly gain a foothold in the hardware parts processing industry.

One of the basic advantages of 5-axis CNC machining is that complex geometries can be machined very easily. Because the tool path is continuous, the cutting tool can follow a complex trajectory that a typical 3-axis CNC machining cannot achieve. Whether it is a planar hardware part machining or a surface hardware part machining, it is necessary to make a more reasonable hardware part machining scheme for a custom hardware part five-axis machining. For example, determining cutting speed, cutting depth, and feed is designed to improve the quality and efficiency of hardware parts custom machining, so as to help hardware parts machining enterprises solve problems such as poor production equipment and low productivity.

During 3-axis CNC machining, operators sometimes have to break the machining process by turning the tool parts to enter hidden areas of machining. Therefore, they must stop the process and perform mathematical calculations for each step of the process. In some cases, fixtures need to be made to hold the part at a specific angle.

Each time a part must come out of the machine and rotate at an angle for processing, the starting position needs to be reset. Resetting the zero (origin) position reduces the positioning accuracy of part features in 3-dimensional space.

By using 5-axis CNC machining, the tool can easily reach areas that are invisible to 3-axis machining, while the tool length is shorter. By using a shorter tool, the vibration of the tool decreases and the surface finish becomes better. For example, the technological characteristics and performance of some metal hardware parts, the five-axis machining needs to take into account the appropriate environmental requirements. In addition, choosing the five-axis machining of hardware parts can also reduce the surface appearance of hardware parts by matching the appropriate tool and strength.

In many cases, 3-axis milling can be more cost effective than 5-axis machining. However, labor costs are a key factor when CNC operators need to load and uninstall parts multiple times, especially in high or mass production.

In addition, if machining parts in 3-axis milling requires making fixtures, this increases the value and advance of CNC machining parts.

The requirement of custom machining quantity and machining cost should be considered when making hardware parts five-axis machining. Because if hardware parts are made in greater demand and have more complex machining shapes, It can easily result in poor precision and heavy cost of hardware parts. The choice of five-axis machining can effectively adjust the effective stroke with the geometric specifications of the machine tool itself. At the same time, the position, cushion and feed of hardware parts are optimized and adjusted to improve machining precision and machining speed.

Through our Factory fourteen years of CNC processing experience, continuous, efficient and trusted services play a very important role. No matter how complex the design or material is, the factory can put the customer’s experience first to ensure a stable quality and delivery period. It is important to ensure quality and stability of delivery period.

I think of service first, punctuality second, price third, quality last. You may disagree. How can quality not be the first? Listen to me slowly analyze it for you.

We’ll often come across different offers. When we see expensive quotations, we should think why?

Good supplier quotations must always have a basis, such as the price of materials, current market conditions, such as precision requirements, the delivery period will affect the price. It’s obviously unreasonable to judge a factory just because of the unit price. Is there any way to make the price more appropriate, to make the delivery time more timely, to keep the quality stable this is what a good processing plant needs to do.

Try to understand the supplier’s supply chain and know the cost level of his supplier to know the cost level of the supplier. Generally speaking, a traditional mold factory has three profit points: material cost, processing cost and management cost; So be sure to understand the price of raw materials.

Therefore,

The choice of large, medium or small scale manufacturers depends on the circumstances.

Generally speaking, many people think that the larger the size, the better, because the larger the size is powerful and well equipped.

But on the other hand, the user’s own choice of initiative will be greatly reduced, and the manufacturer’s product price will be more difficult to accept.

So just choose “door-to-door” automated part five-axis machining, that is, meet your own purchase volume and budget, and can value your automated part five-axis machining.

In addition to the above, when selecting an automated part five-axis process, You must pay attention to whether the supporting equipment of the manufacturer is perfect. At the same time, according to its own actual situation and characteristics, through the company’s various departments to the mold and product demand positioning objective evaluation before making a choice, A satisfactory five-axis machining of automated parts may be found.