Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

It is the most important cost for most manufacturing companies, which includes labor cost, machinery and equipment, material cost, and processing process.

Logistics costs mainly consist of the following major components: transportation costs, packaging costs, storage costs, loading and unloading costs, stagnant material disposal costs.

Mainly for the trial production before mass production, such as prototypes, labor, travel, training, efficiency losses, etc.

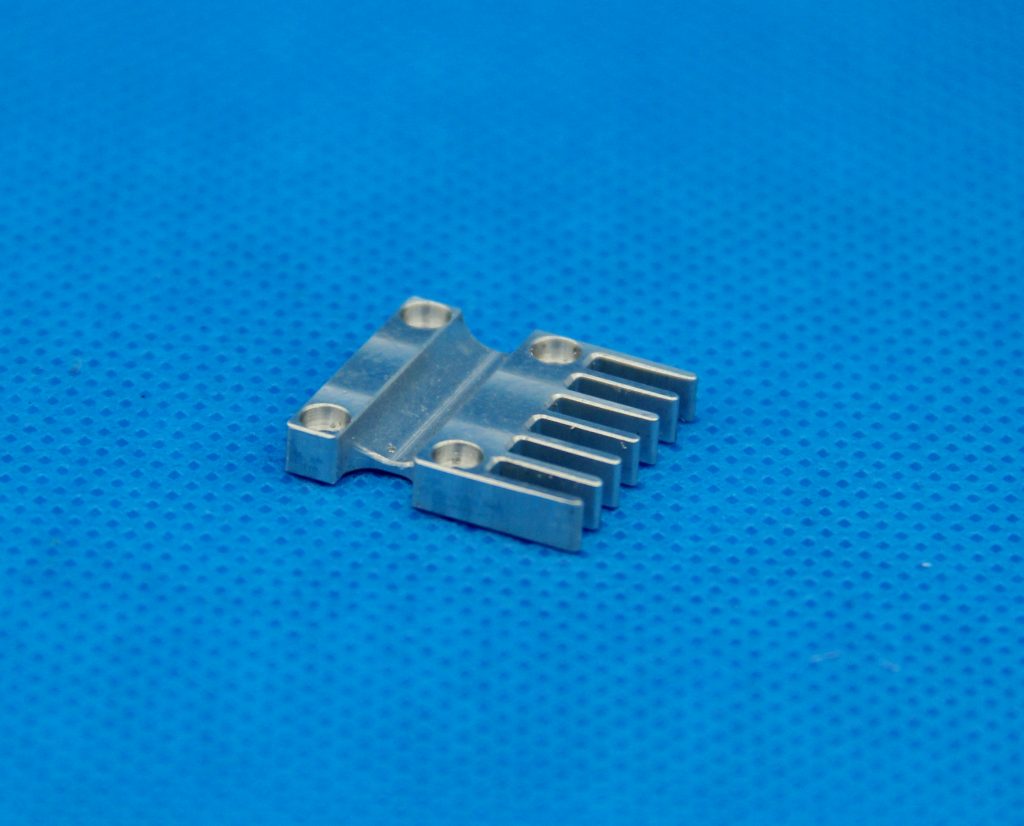

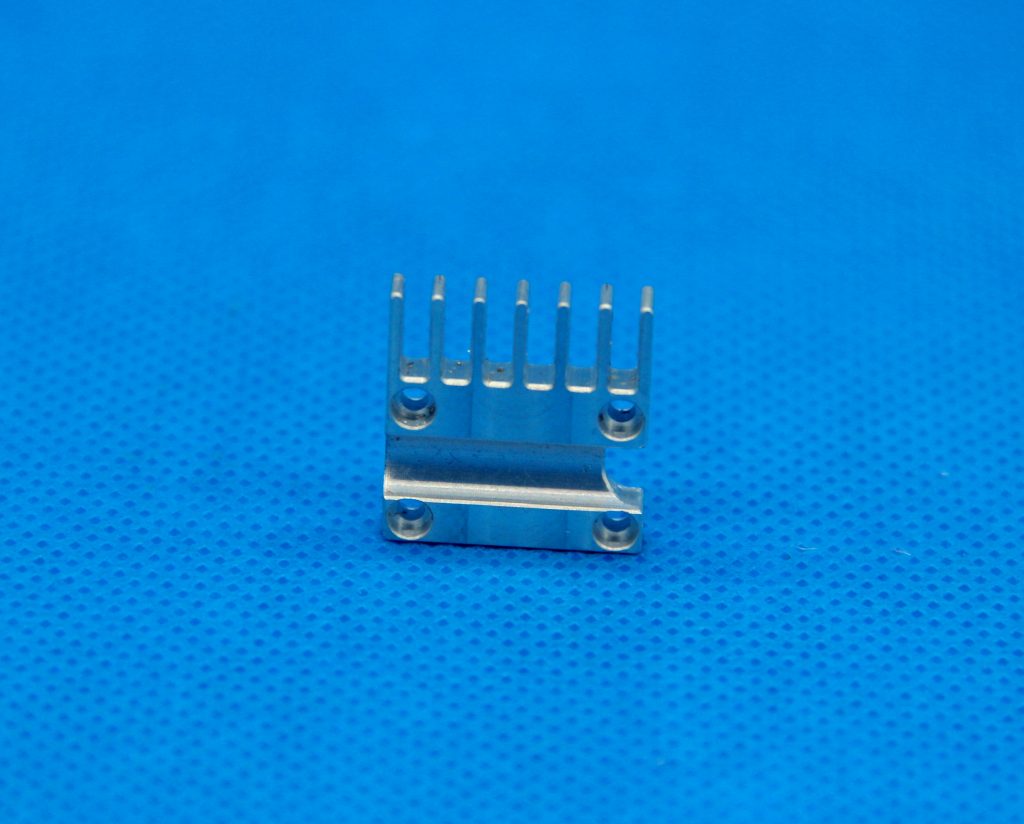

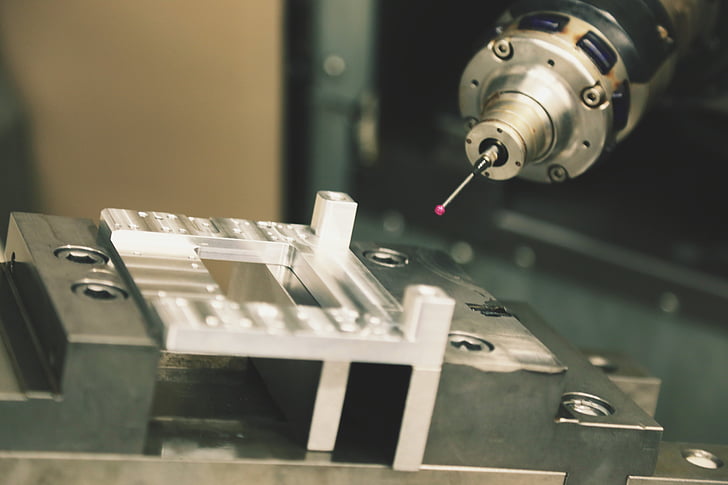

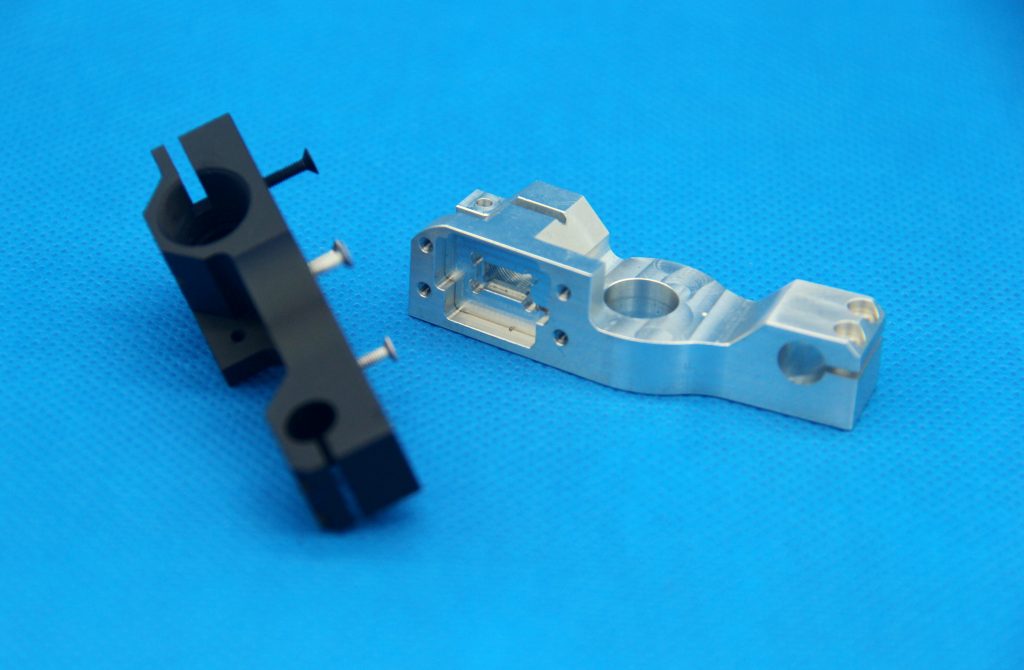

The most important factors that affect the cost of CNC machined parts can be divided into equipment, materials, design, manufacturing volume and finishing operations.

We have already talked about equipment in our previous article. Please see the article.

Material: If the material to be machined is a difficult material, such as stainless steel, material hardness, the need to use tungsten steel hardened tools, and a special cnc machine to be needed with, of course, the cost will be higher than with ordinary materials.

The structure and size of the part to be machined is an important part of the design. If the structure of the product is complex, the machining cost will be much higher; if the overall size of the product is large or the appearance is curved shape, the machining cost will also be much higher.

The production quantity also affects the price, because a very small quantity makes the start-up cost increase.

The accuracy and surface roughness of the part to be machined: if it is necessary to 0.001mm tolerance requirements, both the processing equipment and technical master requirements are relatively high, so the cost will be relatively much higher.

There are also some sharp internal corners, thin walls, deep cavities, non-standard hole sizes and engraving are the reasons for the rise of the finished product, because it will require multiple surface roughness or tolerance checks to increase labor costs and processing time.

That is to say, the factors that determine the cost of CNC machining include machining time, material cost, surface finish, etc. That means the more complex the shape of the sample, the higher the precision required and the longer the machining time, the choice of materials, and the surface treatment are all the reasons for the high price of CNC machining.

Therefore, by reducing the processing time, choosing conventional or standard raw materials, reasonable design of the product, appropriate tolerances, and choosing the right surface treatment can make the cost lower.

So, we know why CNC machining cost is so expensive and how to reduce it now. Hope these tips can give some ideas of reducing the cost of CNC machined parts.

At Componing, our experienced engineers can help you reduce CNC machining cost from all above ways to meet your every demand. Use our online request-a-quote to talk with.